| WARNING! Any project involving the use of electricity is potentially DANGEROUS! You can be badly hurt or even killed by a lot less electricity than you might think! Even a tiny current is enough to potentially stop your heart, if it can get there. AC power as delivered by your electrical utility is even more dangerous than many other sources of electrical energy: the essentially unlimited current that's available can result in your being badly burned, blinded, hurt in other ways or KILLED. If you are not ABSOLUTELY CERTAIN of how to work with electricity safely, DO NOT attempt to do so. Likewise if you do not understand how to wire something in a safe and correct manner: AC line power is NOT the place to practice, as mistakes are all too often fatal. This is ABSOLUTELY NOT a joke! Never work on ANY electrical device unless you are CERTAIN that power has been disconnected. Lock out and CLEARLY LABEL any electrical disconnects, circuit breakers or fuses so that no can accidentally or unknowingly energize a circuit you or anyone else happens to be working on. |

|

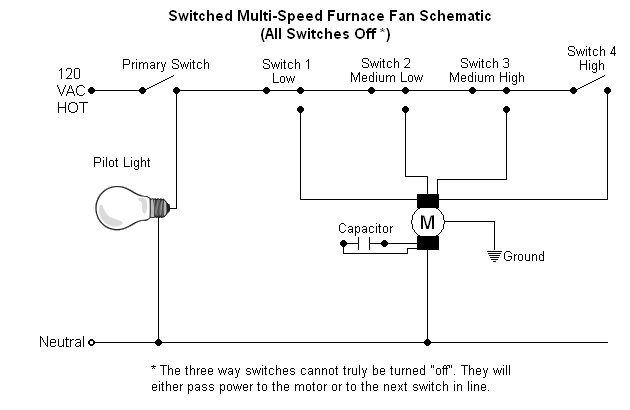

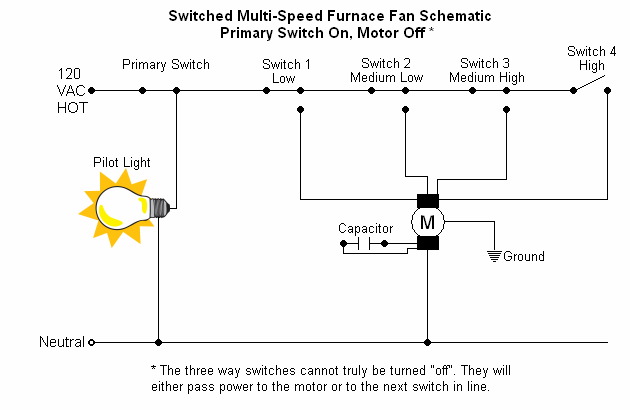

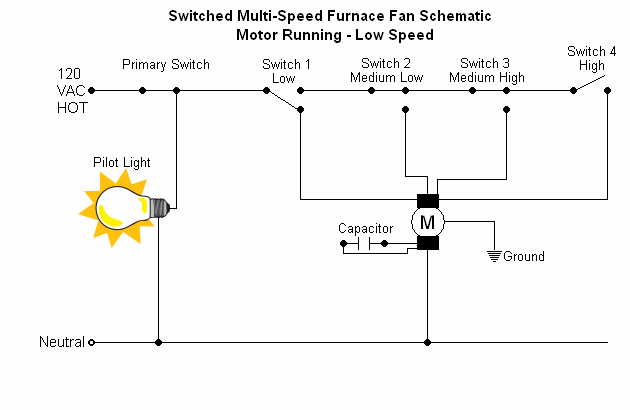

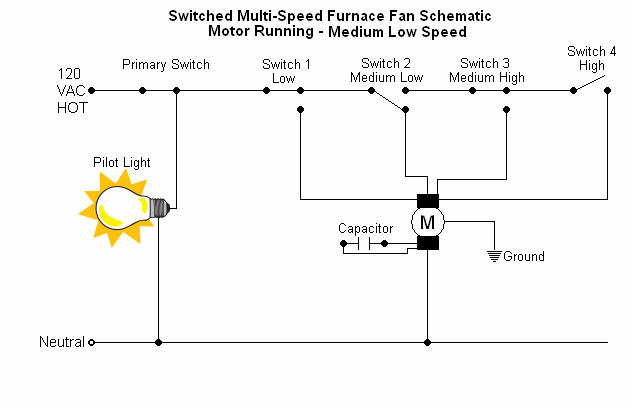

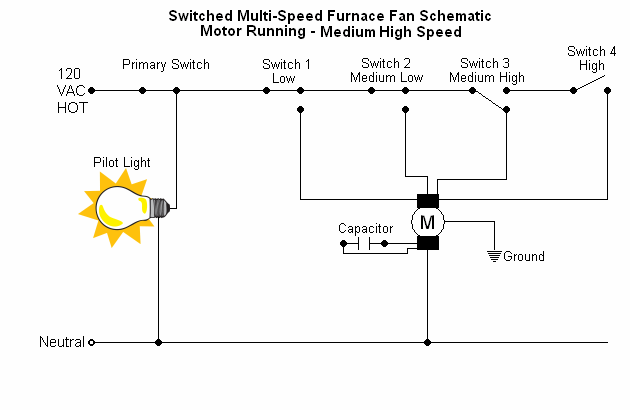

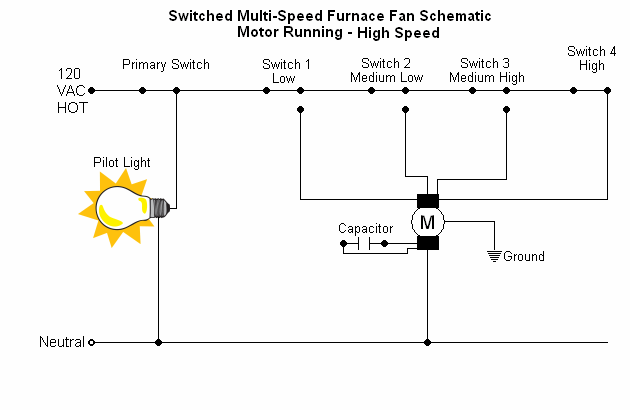

Motor Speeds vs. Switch Position |

||||

|---|---|---|---|---|

|

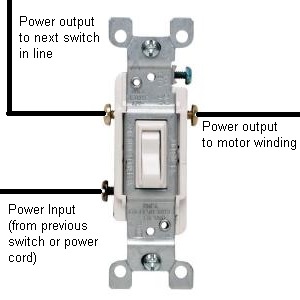

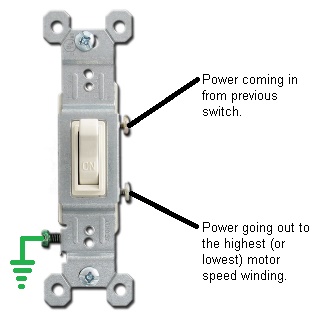

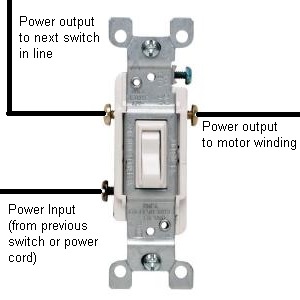

Switch #/Type |

Motor Speed |

|||

|

Switch Four On (One Way) |

|

|

|

HIGH |

|

Switch Three On (Three Way) |

|

|

MEDIUM HIGH |

|

|

Switch Two On (Three Way |

|

MEDIUM LOW |

|

|

|

Switch One On (Three Way) |

LOW |

|

|

|